Milky Lab Mozzarella Line 375 kg/H

Milky Lab Mozzarella Line 375 kg/H

Descripción

Milkylab Mozzarella Coocker, Stretching and Moulding Line : 375 kg per hour

Milky Lab Mozzarella Line 375 kg/H

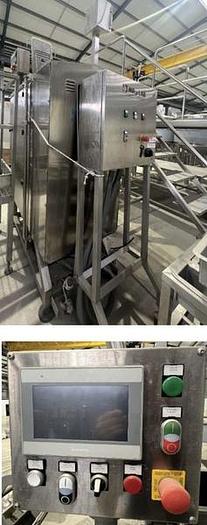

COOKER STRETCHER

TECHNICAL DATA:Dimensions:cm 170x80x240

COOKER AND STRETCHER - TECHNICAL DATA

The product stretching - melting happens by direct steam injection, or with steam injected into the jacket.

N. 2 bi-directional augers activated by N. 2 independent motor reducers (mod. Sew- eurodrive – low

consumption) with adjustable speed by Inverter.

Parts that come into contact with the product are shot-peened with quarz microspheres and the augers

feature Teflon coating.

Thermoregulator with digital display for temperature control

Autonomous CIP washing system, incorporated in the machine.

Electrical control panel in AISI 304 stainless steel equipped by a “touch screen” panel and PLC Siemens

Easy use of the machine thanks to recipes set in the PLC.

Filter to sterilize steam complete with filtering cartridge.

Product unloading by pneumatic exit door.

MOULDING MACHINE

Dimensions

cm 110x120x190 h

Weight 150

kg

200 – 1.000 kg/hour Depends on the shape / the weight of the product

Material : AISI 304 stainless steel

ACCESSORIES

Moulding roller for mozzarella balls from 1 gr up to 650 gr

Moulding roller for pizza cheese

Moulding roller for special shapes

Moulding roller for string cheese

Conveyor for continuous cords, twisted cheese and flat dough

Pneumatic conveyor for blocks up to 3,5 kg

Dosing system for burrata

TECHNICAL FEATURES

Entirely built in AISI 304 stainless steel

An electrically-heated jacket allows the product to be kept constantly at the ideal moulding temperature

A variable-axis machine body in order to regulate the softness of the product

N. 2 augers completely remouvable, diam. 150 mm, built in AISI 304 stainless steel

Moulding roller diameter 215 mm, 350 mm long, built in polyetilene high density, certified for food contact

The moulding rollers and augers are speed adjustable by inverter

The parts in contact with the product are entirely teflon-coated in order to be non-stick

Electronical control panel manufactured in AISI 304 stainless steel IP 65 protection

Thermoregulator with a digital display to control the temperature

Electronic rev counter with a digital display, to calculate the turns of the moulding roller / the number of the

products

Safety sensors and protection according to the CEE rules

Moulding roller of gr. 125

Moulding roller of gr. 200

Especificaciones

| Condición | Usado |